Model the Complexity

B&B-AGEMA meets future energy needs

with hydrogen-fuelled gas turbine technology

By Elspeth Mosedale

The challenge of energy for the future (why hydrogen?)

The global demand for energy continues to increase, with the impetus now behind ensuring as much energy production as possible is from clean sources. Whilst low NOx renewable sources have seen a dramatic increase (from 5451TWh in 2000 to 9824TWh in 2019), large-scale energy storage is still a challenge. There is still a need for energy production to backfill when solar and wind-power are off-line. Using hydrogen as a gas turbine fuel offers the possibility of clean production that can be brought on-line to produce energy in renewable downtime.

Hydrogen combustion is not entirely straightforward. Because of its extreme flammability range and flame speed it easily leads to flashbacks and needs the right combustion technique to keep NOx production low. Wet NOx combustion is the current method used, where water or steam is injected into the combustion chamber to reduce the combustion temperature. The water/steam must be free from impurities, while reducing the NOx emissions this method is still not environmentally sound or efficient. “Dry low NOx” (DLE) offers an alternative, but the combustion process handling requires that engineers think outside the typical “lean combustion – low NOx” box and develop new techniques.

Micromix technology

The most promising and flash-back safe combustion technique relies on Micromix combustion technology. This is achieving lower NOx emissions without large water usage and delivering dry low emissions (DLE) technology. Micromix technology has been in research and development since the late 1980s by Aachen University of Applied Sciences (AcUAS, FH Aachen), and subject of many collaborative projects – mainly together with B&B-AGEMA and Kawasaki Heavy Industries Ltd., Japan (KHI). The two basic ideas behind the concept are explained by Jens Dickhoff from B&B-AGEMA:

- In order to suppress NOx formation, one can either lower the flame temperature or reduce the residence time of fuel/air inside the high temperature zone of the flame. NOx molecules can only form under certain fuel/air conditions and high temperatures. If the N and O molecules reach colder zones behind the flame before they undergo a chemical bond, they literally “missed their chance”.

- Pure hydrogen cannot burn. A diffusion flame is consequently flash-back safe whilst pre-mixed flames will always bear a very destructive risk. This led to the concept of multiple miniaturized diffusion flames, which simultaneously prevents flashbacks and suppresses NOx production.

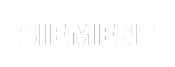

Early designs used cold flow mixing: a hollow perforated plate filled with hydrogen, which allowed air to transition through the holes. This technology was not easy to manufacture at a large scale and also led to some hotspots at the hydrogen injection ports. The next generation incorporated tubes on the hot side of the plate to control where the air mixed with hydrogen, aiming to ensure rich and lean zones that lower NOx emissions. However this hydrogen layer was quite irregular and so proved impractical and costly. Building on this, the improved design kept the perforated plate but with bigger holes and an air jet. The hydrogen is then injected perpendicularly to the air jet. This design gave lower NOx values but also had some problems with thermal stress, and the overall assembly was complex to manufacture.

Overall, these projects had proved the viability of the Micromix technology. While earlier combustion methods had proved less safe due to the possibility of flashback, this newer method was inherently safe, and the mixing and burning occurs simultaneously after injection. However, it was still possible to refine the micro-mix combustor further, to ensure optimal fuel delivery, enhance the fuel flexibility, part load stability and thermal load, and optimize the design for ease of manufacture – all substantial steps for real engine application.

top: Early versions of the Micromix Combustion Chamber

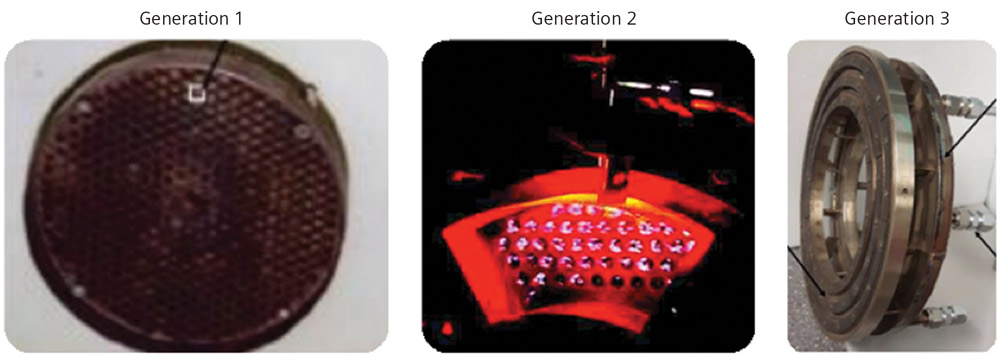

Bottom: 2 Micromix 2D liner burner test rig (Methane-Hydrogen Combustion)

Prototyping and optimization

B&B-AGEMA have been involved in the development of Micromix technology together with its partners from KHI and FH Aachen since 2010. To improve on the fourth generation, B&B-AGEMA used CFD simulation to both understand the combustion characteristics and optimize the design. The ultimate goal was to have low NOx emissions from combustion, while maintaining an acceptable pressure drop in the combustion chamber. Advanced CFD methods proved to be a game-changer in developing this technology.

Using Simcenter STAR-CCM+ they performed intensive CFD investigations of the combustor, looking at the aerodynamic flow parameters and the combustion structures (flame shapes). The aim was to find the optimal design and length of the flame to ensure low NOx combustion and at the same time simplify the design by reducing the number of injectors. The CFD simulations included reactive chemistry to predict the flame shape, size and temperature signature. This was the first time that B&B-AGEMA used this approach. The results from the simulations compared very well with experimental observations from the combustor test bench.

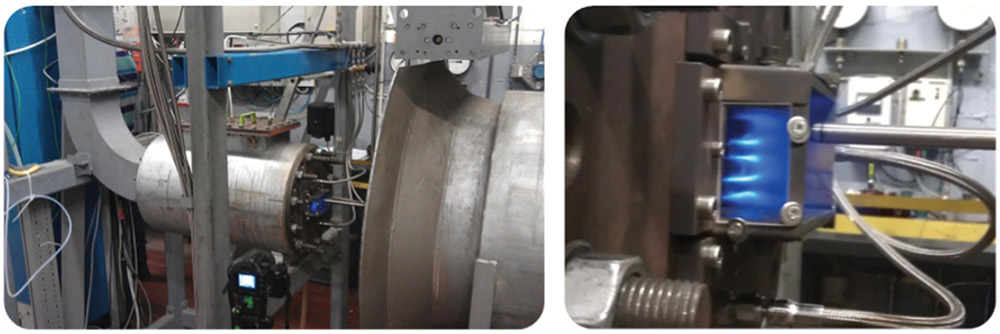

As a result of this research, AcUAS and B&B-AGEMA developed the fifth generation Micromix combustor. With this generation simulation and design exploration became a substantial part of the design loop. Jens explains “We used NX for CAD modeling and Simcenter STAR-CCM+ for reactive CFD simulations. The optimization loop was controlled by HEEDS, so the geometry variation was done automatically. We investigated the response of the flame shape and temperature distribution in the volume behind the combustion chamber, based on the geometry changes”. This approach enabled the team to run many more cases than would be possible on a test bed. As Jens describes, “Design optimization allowed us to accelerate the design, and especially to find new setups and new flame shapes. The CFD simulations have shown a new flame shape with very low NOx properties, which was never considered before”. Having found this design variant, the team manufactured and tested a prototype burner, which proved the flames exist and are beneficial for combustor designs.

Micromix Combustor for APU application; Right: Automated Design space exploration for the Micromix geometry governed by Heeds mdo.

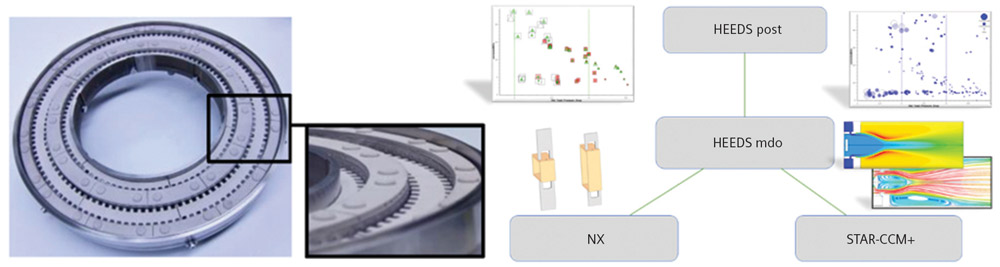

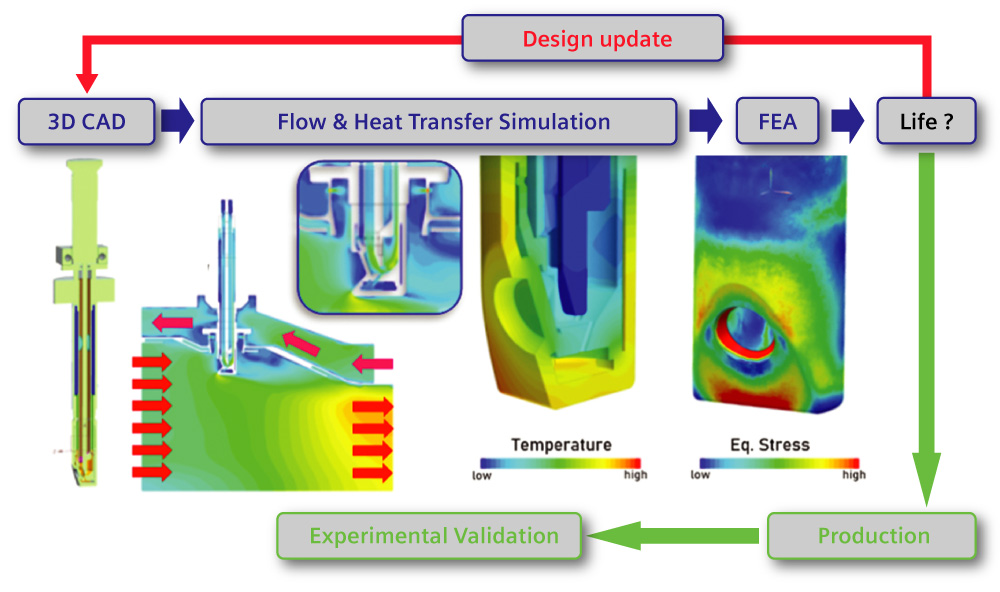

Engineering workflow of the air-cooled borescope development for Micromix flame visualization (white light and infrared) inside the gas turbine combustor end for real engine application

Fuel flexibility

The fuel flexibility of a typical power plant turbine will change in the future, with the shift toward ‘green hydrogen’ and hydrogen-methane fuel mixes. By running conjugate heat transfer (CHT) simulations, B&B-AGEMA was able to assess the impact of different fuel types on the thermal load of the burner. The simulations included detailed chemistry for combustion and both solid and fluid domains. Jens explains “there is a transfer of heat from the fluid domain to the hydrogen bar. If you warm the bar, this energy is fed to the hydrogen gas, which in turn increases the injection depth of the hydrogen into the cross flow. This leads to different NOx results.” This CHT approach improved the agreement between simulation and experimental results, and proved the suitability of the Micromix design for a range of fuel types. Large eddy simulation of combustion

B&B-AGEMA have collaborated with KHI and AcUAS on a succession of projects aimed at developing a hydrogen combustion gas turbine for practical use. During this cooperation, B&B-AGEMA ran intensive numerical simulation projects on the Micromix burner, both for verification and design optimization, building on the work described above. One thing the team investigated was the potential use of Large Eddy Simulation (LES) in the combustion simulations. LES is a transient technique where the large scales of the turbulence are solved explicitly, and the small-scale motions are modelled. In comparison, steady RANS methods model rather than resolve turbulence. Whether a turbulent eddy is resolved or modelled by the LES scheme depends on the local grid resolution, which means that LES calculations require fine computational meshes and small timesteps. This can make this approach computationally expensive, but in this case the results were clear. Jens explains: “RANS simulations tend to show a very stretched, long flame, but this is not the case for LES. The flame shape matches much, much better with the real flame impression. We could predict NOx values which are very close to the experiment. We have never seen such good results before. They even provided an explanation for a transient phenomenon about which we have speculated and discussed many times based on experimental and steady RANS results. With RANS results we just had tendencies correct. Now we have the quantitative values and transient behaviour also correct.”

Optimizing monitoring tools

Throughout the Micromix design process, B&B-AGEMA also developed monitoring tools. One example is the air cooled borescope: this is an optical monitoring device equipped with an infra red or white light endoscope which is inserted into the combustor to monitor the flames. The Borescope has to be able to withstand the high temperatures within the combustor which can reach up to more than 1450°C. B&B-AGEMA combined CHT simulations and FEA analysis on the borescope geometry to predict stress curves and lifetime for the component. They simulated a range of alternative designs, aiming to optimize the internal cooling pathways and ensure structural integrity. The final design was then manufactured: in tests this prototype was successfully operated in both high and low pressure combustion tests of the brand new hydrogen combustor from KHI applied with the MMX combustion technology. From theory to reality: the world’s first DLE turbine

The overall aim of this project was to lower the NOx values for hydrogen-driven combustors, while ensuring acceptable pressure drop in the combustor. The target was to have less than 35 PPM NOx at 100% hydrogen from 50% to 100% load, with low NOx values at part-load operation as well. Additional requirements were a stable ignition all the time, no flashback risks and an acceptable pressure drop of 3.5%. With their intensive program of CFD simulation, design optimization and benchmark validation, B&B-AGEMA, KHI and the AcUAS created a Micromix burner design which successfully met all these targets. Simulation was key to their success. Jens comments: “For B&B-AGEMA the Siemens software portfolio is the clear market leader for turbine and combustor flow, chemistry and heat transfer analysis.”

The Micromix design was patented by B&B-AGEMA and KHI in 2016. Thereafter the focus was on implementing this new technology into industrial turbines. On 21st July 2020, after a few years “under the radar” to protect the technology, the Japanese New Energy and Industrial Technology Development Organization (NEDO) and B&B AGEMA’s partner KHI, announced the successful demonstration of the first DLE 100%-Hydrogen-fuelled gas turbine under commercial operating conditions in the port of Kobe, Japan. Jens sums up their thoughts: “We are very excited to see this, and we are also very proud to be part of the Hydrogen Road of Kawasaki. This is a great achievement on the way into the Carbon-free future for electricity production based on the Hydrogen technology”