If I don’t use AI, am I really an engineer?

Busting the myths of artificial intelligence and machine learning in engineering.

By Christina Kothlow, and Krishna Veeraraghavan

As Artificial Intelligence (AI) has become more ubiquitous in our everyday lives, so too has they hype. There are some pretty scary premonitions about AI too, largely thanks to the science-fiction and dystopian literary genre, but even some of the leading lights in science and technology have some strong opinions.

What is AI? AI is a multidisciplinary topic that enables machines, devices, and computers to think and make decisions in a way that would seem intelligent. AI helps machines and programs make smarter decisions by learning and improving in an iterative process based on the information they collect.

In the future, AI in engineering may focus more on collective intelligence. Engineers and computers working together in feedback loops to identify problems and develop solutions that can make the design process and systems work more efficiently. This would enhance the capabilities and contributions of engineers. This sounds positive, a worthwhile contribution to humanity and real people still central.

Collective intelligence Collective intelligence somehow seems more sinister, it refers to ways that data and technologies bring people, machines, and computers together to achieve outcomes that were previously beyond our expectations. Psychologists define collective intelligence as groups whose general ability is to perform well not on a single task, but on a wide range of different tasks. This is possible to achieve by combining human intelligence and machine learning, the ultimate 2+2=5?

Machine learning Machine Learning (ML) takes us even further into science-fiction territory, a subset of AI, a self-adaptive algorithm that uses statistical algorithms to build and train systems and models. These systems and models can learn and improve without being explicitly programmed to do so and then make predictions or identify hidden patterns in the data. Two types of machine learning widely used are supervised and unsupervised learning. All supervised learning will fall under either regression or classification problem. Input data for both cases can be numerical and categorical.

Deep learning Deep learning moves us from science-fiction to potential dystopia but is simply a further subset of machine learning. Some of the most frequently used deep learning networks include convolutional neural networks, auto-encoders, transformers, and generative adversarial networks (GAN). Deep learning utilizes hierarchically organized artificial neurons to process data for extracting higher-level features from the raw input and for achieving machine learning objectives. Deep learning is distinguished by its use of many layers of artificial neurons and, consequently, many parameters and hyperparameters. Optimizing hyperparameters can have an impact on the training of machine learning algorithms (a few examples include number of clusters in clustering algorithms, Bayesian optimization, gradient-based optimization, etc.).

Having established some common definitions, we can do some myth busting.

Myth #1: Numerical models are the only solutions available to solve difficult engineering problems. AI is not accurate enough to be a good fit for Computational Fluid Dynamics (CFD) and engineering problems Reality: Thanks to technological advances, AI/ML solutions now exist that work well on sub-systems with very minimal prediction error. Simcenter Engineering & Consulting Services have worked with customers to use AI/ML in design predictions to minimize CFD simulations with great success and good accuracy.

Myth #2: Data science is easy and there are open-source tools that can be used Reality: Generic machine learning algorithms cannot handle customer-specific engineering problems. Different applications require different machine learning algorithms and further problem-specific refinement (for example shape detection techniques). Although there are widely available image recognition algorithms, companies must develop an in-house shape detection algorithm to detect various shapes or components of a vehicle.

Myth #3: AI doesn’t require people to run it Reality: The value of AI lies in its ability to augment the capabilities of computer engineers and domain experts. By performing the monotonous and repetitive tasks, it helps engineers focus on solving more complex problems using CFD tools, such as Simcenter, to generate more meaningful simulation data for future predictions. AI is the helping hand, not the hand itself.

Myth #4: The more data, the better Reality: AI in CFD needs smart engineering data, such as Key Performance Indicators (KPI), relevant to the problem, to be successful. Simcenter Engineering Services uses feature engineering technologies to achieve data reduction from simulation data to enable AI to deliver high-quality solutions. As with many things more data isn’t always better, but relevant data that gives insight is.

AI – more fact than fiction AI has transformed technologies in every industry. Applying AI to CFD applications can be a strategic asset to companies since it helps to reduce costs and create new differentiated values. AI-driven smart solutions offer substantial benefits to CFD engineers, designers, and analysts:

- Reduce computational, design program, and operational costs by creating more designs per simulation at a faster turnaround time

- Reduce the process and program development turnaround time with ML based surrogate models and smart AI driven workflows to expedite turnaround time

- Enhance the accuracy of simulations by flagging anomalies and providing knowledgebase workflow assistance in the CFD process. This includes CAD, physics modeling, mesh settings, and postprocessing

- Improve product performance and efficiency by creating an ecosystem to simulate, predict, and optimize the product in a seamless way

- Provide knowledgebase workflow assistance in CFD

If AI offers so many advantages for CFD, why aren’t all engineers doing it? Implementing AI, particularly for a niche technology like CFD, can present some operational challenges. Database management: building and maintaining simulation and design database is a monotonous and expensive process which involves alignment with IT and the various engineering groups. Engineering groups themselves are often disconnected, so the required coordination with an additional department can be a hindrance.

Extracting and then training the data for AI in CFD, there is a lack of required data science skills to extract desired features, build and train the data set for integrating ML techniques with CFD, CAE simulations and for design predictions.

Talent, delivering AI capabilities in CFD designs and simulations requires talent in machine learning, deep learning techniques and CFD skills, and these skills are still largely developmental across the engineering workforce.

What’s the solution? The Simcenter Engineering Services group at Siemens has developed AI solutions for CFD to solve these and other AI-related problems companies face. These solutions enable companies to:

- Connect CFD with AI and multi field science to assist engineers in multi-physics design exploration studies and AI-enabled control actions to enhance product performance

- Drive innovation in designs and simulations by enhancing their digital twin capabilities, by developing and deploying customizable AI solutions

- Realize successful transformation for AI in designs and simulations by providing domain knowledge, build and train ML models with CFD and multi-science data and provide access to deep learning and ML techniques

Going beyond CFD Industrial solutions for AI in simulations have been developed with the Siemens groups including model-based systems engineering, predictive analytics, physical testing, and system simulation engineering. These synergies allow the Simcenter Engineering Services team to leverage domain expertise and deliver value that goes beyond CFD by focusing on AI/ML and statistical techniques that address customers goals.

If this all sounds theoretical and futuristic, then keep reading.

Real-world applications for AI in CFD Predict discrete temperature using ML For engineers responsible for thermal management, regression techniques can be used to develop a prediction algorithm based on input data (such as numerical/categorical) and output data (numerical).

In the above example, the team trained a neural network to predict the average temperature of a vehicle. Completed using 500 random samples from 600 data samples generated by Simcenter for various combinations of operating conditions. The KPI (temperature) was extracted to train the model. Of the 600 samples, the team used 500 for training, and the remaining 100 were used to predict the accuracy of the model. Of 100 data samples, 72 samples had less than 1% prediction error (difference in predicted temperature – actual temperature) and 28 samples had prediction error in the range of 1% to 1.66%. The maximum prediction error in the model was 1.66%, which corresponds to the temperature difference of <5 ⁰ C.

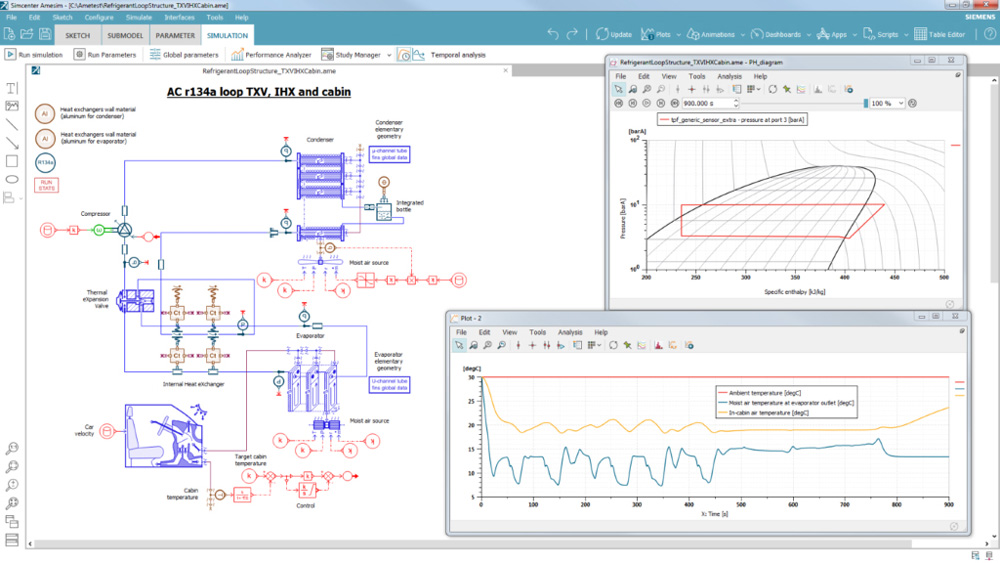

Regression techniques can also be integrated with control systems. Using CFD data, engineers can train the regression model, use it to predict values of relevant variables, and then take corrective control actions to achieve the desired target and improve performance (for example, based on the battery range remaining). Additionally, the model can predict the energy load and invoke control actions to adjust the cabin temperature accordingly.

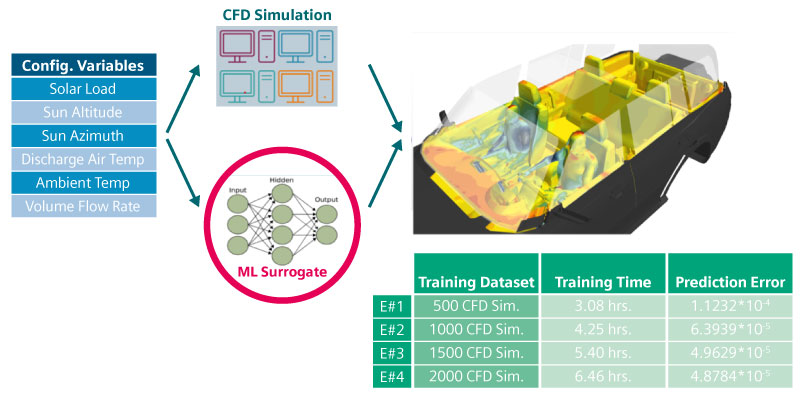

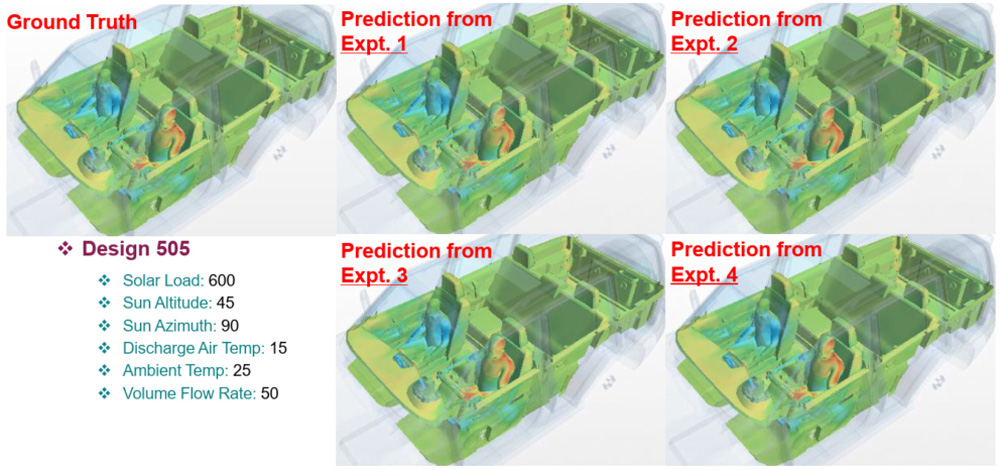

Predict cabin surface temperature using a convolutional neural network In a similar example, the Predictive Analytics team used data samples to build a convolutional neural network to predict the surface temperature distribution inside a vehicle cabin. In this exercise, a simulation database was generated by running CFD simulations for various operating conditions. While the team tested the application of 500 (Expt.1), 1,000 (Expt.2), 1,500 (Expt.3), and 2,000 (Expt.4) data samples to train the network, the prediction error remained stable. The team tested the accuracy of the neural network prediction with the actual CFD simulation results and found that the results from both techniques matched. We followed the below steps to compute the prediction error:

- Computed the square error between the true pixel value and the predicted pixel value

- Normalized it by the true pixel value

- Computed its average over the entire region.

These tests proved to the team that AI techniques can be used for CFD simulations without compromising accuracy. By applying techniques such as those listed in the examples above, companies can free up their engineers’ time and enable them to perform more valuable, complex design and simulation tasks while maintaining accuracy. Further live examples can be viewed here Back to the question we posed at the beginning: if I don’t use AI, am I really an engineer? The answer today is yes, but in three years maybe not.