Go Faster

Shooting for the Stars

Launching Satellites with Simcenter

By Luke Morris

Did you know there are currently almost 2,000 individual satellites in low Earth orbit? And this number is expected to increase exponentially as continued miniaturisation in electronics fuels the growth of the small satellite market over the next decade. By 2030 it’s predicted that a further 8,600 small satellites (weighing less than 500kg) will have been launched. This equates to a market worth an estimated $42.8B USD, with about 30% going to launch costs, and growth of 22% CAGR.

But to get a satellite into space you need a rocket. And rockets don’t come cheap. So how are companies going to launch their satellites at the right time and place whilst keeping costs under control?

Currently, small satellite companies have to book space on a large rocket, tagging along with a big payload. This causes high lead times of up to two or three years and if the main payload has to change orbit, they may have to find another rocket meaning further delays. All in all, it’s a frustrating and inefficient process.

Dedicated launch services for everyone Reaction Dynamics (RDX) was founded in 2016 by CEO, Bachar Elzein, to address this exact issue. The startup has developed a breakthrough rocket technology that provides the means for an eco-friendly launch solution. Leveraging its breakthrough green hybrid rocket engines, the company's launch technology will pave the way towards clean access to Earth's orbit at a fraction of currently available prices.

Hybrid rocket engines are nothing new – they’ve been around since the 1930s – but previously they have only been able to run at peak performance for a few seconds. As a result, satellite launch companies have used more complex and more expensive liquid fuelled rocket engines. However, RDX’s invention provides better performance over longer duration burn times than any previous hybrid rocket engine – and most importantly, good enough to reach orbit. The propulsion system is much simpler than that of other rocket engines, making manufacturing much cheaper and reliability significantly higher as there are fewer parts that can fail. This also means that vehicle production can be scaled rapidly and, combined with the ease of handling of the propellants, enables a rapid and responsive launch service.

RDX will be manufacturing and operating its own orbital rockets for small satellite launch as a service. Priced at $15,000 USD per kilogram this will compete with other small launch companies as well as some heavy launch companies. The key difference is that RDX provide a dedicated ride at a similar price point to a rideshare on a large rocket. Elzein describes it as “Offering customers a taxi service for the same amount you’d pay for a bus. They can decide exactly when and where their satellites are launched rather than waiting for a rocket that happens to be going in the right direction.” The simplicity of the design means the rockets can be built and launched very quickly, enabling rapid response times which would be ideal for the reconstitution of damaged or destroyed military assets in space. With RDX’s dedicated small satellite service, customers will have full control over the schedule and can have their satellite in orbit within a matter of weeks instead of waiting up to three years to ride along on a bigger rocket. RDX can always find the correct launch point for the required orbit as they have access to spaceports across the world. And for smaller operators who can’t afford a dedicated rocket, their service can be sold to launch brokers who will aggregate small satellite payloads.

So how have RDX managed to design their new hybrid rocket engine which is set to revolutionise the satellite launch industry?

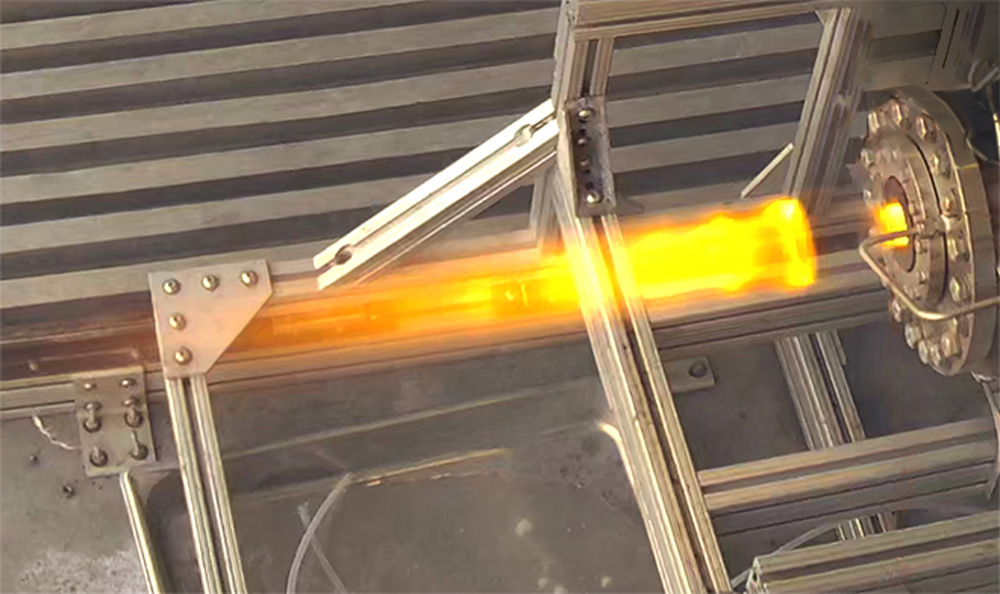

Reaction Dynamics’ engine test cell

Maya HTT guides the way with Simcenter Elzein and his team knew they would need the most robust simulation tools, combined with high-fidelity analysis, which is why they engaged with Siemens and Maya HTT. Maya HTT is a Siemens Solution Partner, working with companies like RDX to help them realize the full potential of Siemens Digital Industries Software. Maya HTT’s expert engineers enable them to make the most of simulation and virtual prototyping to improve performance, quality, and efficiency, whilst reducing overall development costs.

“The quality of the support and the versatility of Siemens’ suite of industry software made it a clear winner,” says Maxime Goulet-Bourdon, Propulsion Test Lead at RDX. “The integration of so many features within the Simcenter platform means that scaling our simulation capabilities as required becomes efficient and realistic, allowing us to step comfortably into simulations to get the confidence that our designs will respect the applicable norms. Furthermore, the quality of the support received whenever small issues popped up was always great and timely. We know that we can count on the team at Maya HTT to guide and help us through the deployment and adaptation to these new and powerful tools, making us obtain results faster.”

Christophe Leclerc, structural design lead at RDX points to CAD integration as a key factor: “For design and analysis, Simcenter is the best option for us, as it enables seamless transition from CAD to simulation, by streamlining the process of simplifying and cleaning up complex design models to prepare the analysis models. This can help accelerate the design process greatly, during which hundreds of iterations can be necessary. Multiple add-on modules, such as the Laminate Composite module, are also available, enabling us to quickly grow our capabilities when necessary, without having to go through the lengthy process of transitioning toward a new software solution. Being integrated inside Simcenter, also gives us flexibility in our usage, by enabling the creation of an ecosystem where all of our software needs, from CAD to PLM, and including a wide range of simulation tools, are fulfilled by a single platform. For a startup, this ability of the platform to grow with us is of great importance when choosing the best solution.”

Bachar Elzein, Reaction Dynamics Founder

Elzein says the development of RDX’s revolutionary rocket engines would simply have been more resource intensive without Simcenter and they are continuing to discover more benefits from the software: “After switching to Simcenter for the seamless CAD integration and analysis we’ve been gradually adding more packages and licenses such as Design Explorer and Simcenter Nastran. Each one reduces both our development time and costs as shorter iterations lead to better products sooner.”

RDX will shortly be announcing a demonstration flight using the same rocket engine that will be used to put satellites into orbit. They are then aiming a first orbital commercial launch within the next two years. To find out more, head to https://www.reactiondynamics.space/.

First iteration of the orbital engine tested in early 2021