GO FASTER

ABEC: Taking the ritual out of bioreactor design

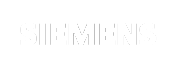

From lab-scale to industrial-scale

By Stephen Ferguson

Image provided by ABEC

Science or magic? The origins of biochemistry

Humans have been using microorganisms to transform raw materials into useful products since before the dawn of history through fermentation. Before the discovery of microorganisms (such as yeast and bacteria) about 350 years ago, this process must have seemed like magic. Indeed, fermented foods, drinks and sometimes medicines are part of every culture and are often bound up in ancient rituals that somehow provide the perfect conditions for a complex biochemical process.

Wine, bread, yoghurt, sauerkraut, and kimchi are all the result of biological reactions in which single-cell organisms (such as yeast or bacteria) transform boring (and often unappetizing) ingredients into a delicious (and sometimes intoxicating) end product.

However, in our hygiene-obsessed refrigerator-equipped modern world, most of us have come to regard bacteria as a threat to our health rather than as a potentially beneficial processing agent. We tend to delegate fermentation (and other biochemical processing) to experts in labs and industrial processing facilities.

Industrial biochemistry

Since the 1970s, our species has become highly competent at using biological agents such as cell cultures, microorganisms or enzymes for biological processing on an industrial scale. Indeed, in many ways, humanity has become entirely dependent on these processes for our continued survival.

At the heart of these industrial processes are bioreactors: vessels in which carefully controlled biological reactions are performed. Many are used to grow cells or other micro-organisms for these processes.

In addition to their role in food production, bioreactors are used today to produce pharmaceuticals, antibodies and vaccines, including playing a critical role in responding to the Covid-19 pandemic. Increasingly bioreactors are also being used to grow mammalian tissue from stem cells, either for transplant purposes or as a source of low-carbon guilt-free meat.

And those ancient brewing processes that intoxicated nearly all of our ancestors? They are being redeployed on an industrial scale to create low-carbon bio-fuels from corn.

The simplest bioreactors involve lab-scale experiments using Petri-dishes and shaken flasks, which are used to demonstrate the viability and efficacy of a biochemical process. At industrial scale, bioreactors are typically large cylindrical tanks that are agitated using an impeller.

Every medicine ever developed - every vaccine - and every biochemical process started in a lab, developed and tested in small batches until it was ready to be produced in large quantities, often in multiple production facilities across the globe.

Therein lies the challenge – biological processes do not scale linearly with the geometric size of the bioreactor. Maintaining the ideal cultivation conditions developed in a 10-litre bench experiment in a 4000-litre industrial bioreactor is a difficult engineering problem.

Image provided by ABEC

Scaling up: the ABEC way

In the pharmaceutical world, the undisputed experts in the bioreactor scaling process is ABEC, a company which has provided engineering, equipment and services to the biopharmaceutical industry throughout the world since 1974. ABEC provides custom-engineered solutions for the life sciences industry, supporting their efforts to create life-changing therapies. The company offers a range of engineering solutions for manufacturing therapeutics. Since its inception, ABEC has enhanced its capabilities as technological advances became available.

At the beginning, customer systems were being operated manually, but today ABEC assists the biopharmaceutical customer in bridging different platforms, from small to large, to ensure the same results are achieved everywhere.

We spoke to Paul Kubera, vice president of process technology at ABEC, to find out about the critical role that simulation plays in that process.

“A typical scenario might involve a project that has moved from the laboratory bench at the tens-of-liters scale to process development, which may be operating on a few hundreds-of-liters scales. And then into production where they need to ramp up by thousands of liters in multiple units,” said Kubera.

The challenge with bioreactors is keeping the host-cell-platform alive. According to Kubera, “The growth of the organism must be supported – it needs food, a carbon source and to take in oxygen and give off carbon dioxide. It is critical to be able to deliver a known amount of oxygen in a given timeframe and remove carbon dioxide for all the organisms in the vessel.”

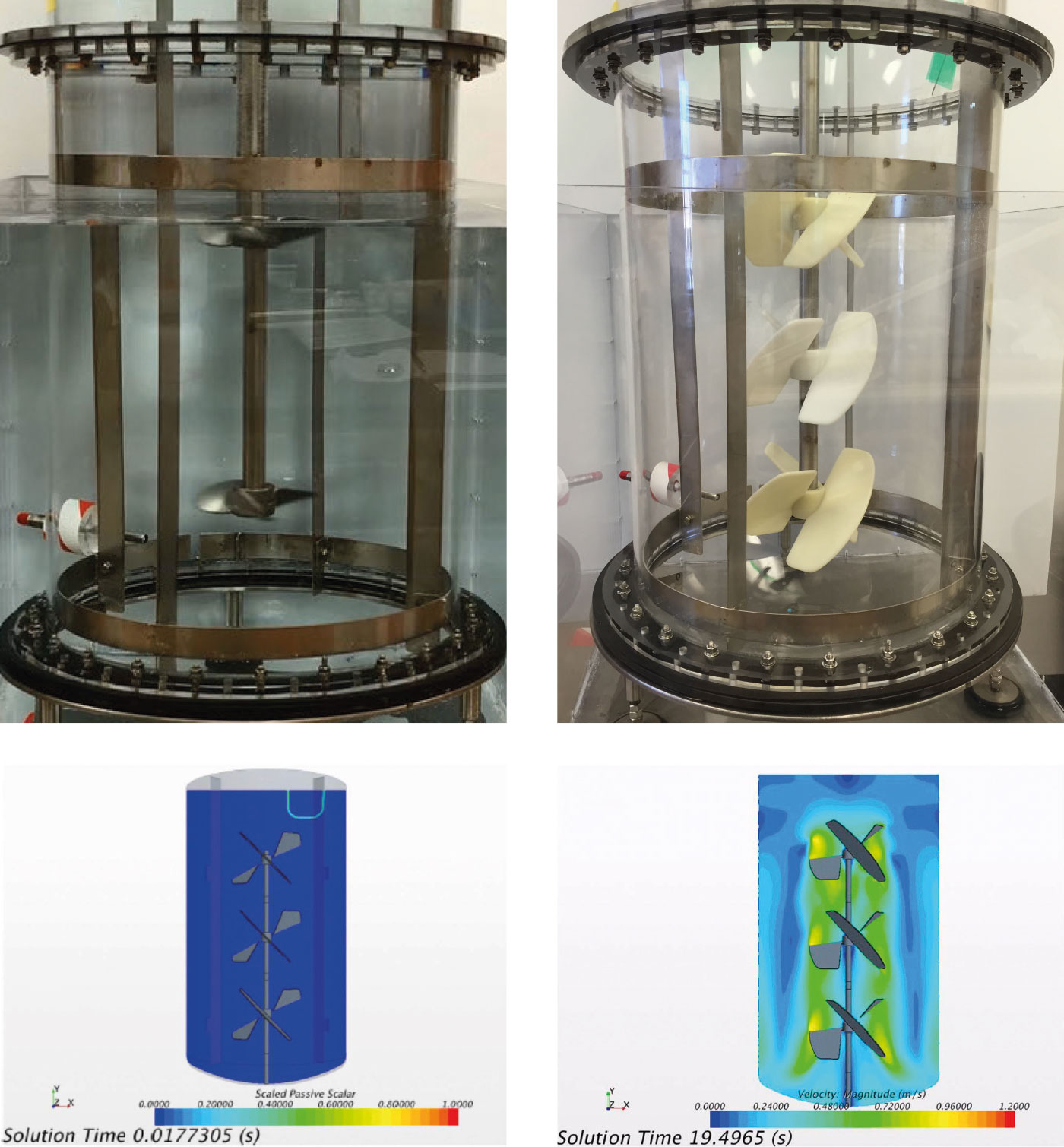

So the problem is essentially one of mixing: providing ensuring that all the organisms are exposed to relatively homogeneous environment for the weeks, or even months, that it takes for biochemical processes to be effective.

It’s a classical fluid dynamics problem but with one caveat: the working fluid is literally alive. Therein lies the challenge: as the scale of the vessel increases, so do the turbulent shear stresses used to perform mixing. If not carefully controlled, these can harm or even kill the cells.

In the traditional vaccine development process, which took many years, this scale up process was often lengthy and expensive, and based mostly around trial and error. However, ABEC has found the most effective process includes desktop calculations, small-scale tests to generate data and validate CFD, full-scale CFD modeling and full-scale confirmation testing. ABEC relies on Siemens Simcenter STAR-CCM+ software for performing CFD simulations.

Image provided by ABEC

“With Simcenter, we can run a computational simulation of the laboratory configuration and confirm the same results. We can then run a large-scale simulation and be confident that the measured performance of the delivered equipment will track with expectations,” said Kubera. “As an example, we demonstrated that we can cut blend time 50 percent by using laboratory tests to screen options and Simcenter simulation to extend the results.”

“Siemens provides us with the support we need to demonstrate to our customers this equipment can operate in a very predictable fashion immediately upon startup, reducing their time-to-market. Our relationship with Siemens Digital Industries Software helps us very capably provide that service.”

As valuable a tool as Simcenter STAR-CCM+ is for ABEC, they are aware that it is capable of even more: “We don’t perform enough CFD to take full advantage of all that it can do for us,” says Kubera. “Siemens provides us with the support we need to demonstrate to our customers this equipment can operate in a very predictable fashion immediately upon startup, reducing their time-to-market. Our relationship with Siemens Digital Industries Software helps us very capably provide that service.”

ABEC continues to innovate, recently introducing the 6,000-liter Custom Single Run™ bioreactor, effectively tripling the industry-standard capacity for single-use bioreactors.

While modern industrial bioreactors might not rely on as much actual magic as the ancient fermentation processes pioneered by our ancestors, it should be clear that Simcenter has helped remove much of the ritual from the process and replace it with science.

Images provided by ABEC